English ![]()

Views: 0 Author: Site Editor Publish Time: 2026-01-12 Origin: Site

Did you know that a unique alloy is changing the way medical devices are designed? Nitinol, a nickel-titanium alloy, boasts remarkable properties like superelasticity and shape memory. These qualities make it a game-changer in medical technology.

In this article, we will explore how Nitinol is revolutionizing medical devices, from stents to orthopedic implants. You'll learn how this material's unique properties are improving patient outcomes and driving innovation in healthcare.

Nitinol is a remarkable material known for its superelasticity and shape memory effects. Superelasticity refers to the ability of the material to undergo significant deformation but return to its original shape once the stress is removed. This unique property is particularly valuable in medical applications, where flexibility and resilience are required. For instance, Nitinol guidewires in angioplasty must bend and flex to navigate through tortuous blood vessels but then return to their original shape without damage.

The shape memory property of Nitinol allows it to revert to a predefined shape when heated. This effect is based on the material’s transformation between two different crystal structures — austenite (stable phase at higher temperatures) and martensite (stable phase at lower temperatures). When the material is deformed in its martensitic phase, heating it above a certain threshold temperature causes it to “remember” its original austenitic shape. This behavior is crucial in medical devices such as stents and catheters, where precision deployment is needed.

Nitinol’s combination of biocompatibility, corrosion resistance, and fatigue resistance makes it ideal for use in medical devices. Biocompatibility ensures that the material can interact with the human body without causing an adverse immune response, making it suitable for implants that may remain inside the body for years. Nitinol is also resistant to corrosion, which ensures that devices made from it remain durable and effective even in harsh biological environments.

Furthermore, Nitinol has excellent fatigue resistance, allowing devices made from it to withstand repeated stress cycles without failure. For instance, Nitinol stents are able to maintain their shape and functionality over time, even when subjected to the continuous pressure of blood flow.

Nitinol stents are a breakthrough in cardiovascular interventions. These self-expanding stents are designed to be inserted into blood vessels in a collapsed form, and once deployed, they return to their original size. The ability of Nitinol to expand under its own force allows for minimally invasive insertion through small incisions, reducing the need for complex surgical procedures.

Nitinol stents have proven to be highly effective in maintaining proper blood flow in patients suffering from peripheral vascular diseases. Studies have shown that Nitinol stents offer superior long-term outcomes compared to traditional stainless steel stents. For instance, the primary patency rate for Nitinol self-expanding stents in femoropopliteal artery disease was reported at 83.2% at 12 months, significantly higher than the 64.8% for balloon-expandable stents.

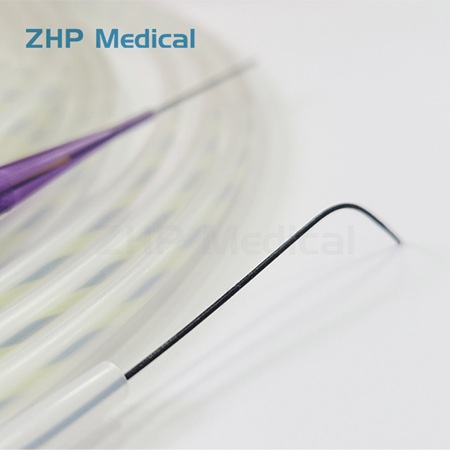

Nitinol guidewires are another essential application of Nitinol in medical technology. These guidewires are used to navigate through complex vascular pathways during minimally invasive procedures. Their flexibility, kink resistance, and excellent maneuverability make them a preferred choice over traditional stainless steel guidewires.

The superior torque control and flexibility of Nitinol guidewires reduce the risk of vessel damage during procedures such as angioplasty and endovascular surgeries. Research has shown that Nitinol guidewires reduce procedural complications by up to 25%, making them indispensable for complex cardiovascular interventions.

In orthodontics, Nitinol is used to create archwires that provide continuous, gentle pressure to realign teeth. Nitinol archwires have the ability to maintain their force over time, reducing the need for frequent adjustments. This results in improved comfort and efficiency for patients undergoing orthodontic treatment.

Studies have demonstrated that Nitinol archwires lead to faster alignment in the first six months of treatment compared to traditional stainless steel wires. The ability to apply consistent pressure over a longer period enhances the effectiveness of orthodontic procedures and reduces discomfort for patients.

Application | Key Benefits | Clinical Outcome |

Nitinol Stents | Self-expanding, durable, biocompatible | 83.2% patency rate at 12 months |

Guidewires | Kink-resistant, flexible, precise maneuverability | 25% reduction in procedural complications |

Orthodontic Archwires | Continuous pressure, faster alignment | 30% faster alignment in first 6 months |

Endovascular Clot Retrieval | Shape memory for improved clot retrieval | 49% functional independence at 90 days |

Heart Valve Frames | Self-expanding, minimizes surgical risks | 1.0% mortality rate in TAVR |

Bone Staples | Shape memory, faster healing | 40% faster healing in ankle fractures |

Medical Nitinol is a critical material in clot retrieval devices used for treating strokes. These devices, often in the form of stent retrievers, are designed to remove blood clots from arteries in the brain. The shape memory feature of Nitinol allows these devices to expand and conform to the shape of the clot, improving retrieval success rates.

Studies have shown that patients treated with Nitinol-based stent retrievers experience significantly better outcomes, with a 49% rate of functional independence at 90 days compared to only 13% for those receiving standard care. This highlights the life-saving potential of Nitinol-based devices in acute stroke treatment.

In the field of cardiology, Nitinol is used in transcatheter heart valve replacements (TAVR). These heart valves rely on Nitinol frames to support the artificial valve and enable minimally invasive implantation. Nitinol’s ability to self-expand ensures that the valve is deployed accurately and securely through a catheter.

The PARTNER 3 Trial demonstrated the effectiveness of Nitinol-based heart valves in reducing procedural risks, with a 1.0% mortality rate at one year, significantly lower than the 2.5% mortality rate associated with open-heart surgery. This confirms the role of Nitinol in minimizing the invasiveness and risks of heart surgery.

Nitinol’s use in orthopedic implants has revolutionized the treatment of bone fractures. Nitinol bone staples provide faster and more stable healing due to the material’s shape memory and superelastic properties. These implants are particularly beneficial in spinal surgeries and small joint repairs, where precise fixation is required.

A study published in The Journal of Bone and Joint Surgery found that Nitinol bone staples led to 40% faster healing times for ankle fractures compared to traditional titanium staples. This demonstrates Nitinol’s ability to improve recovery times and outcomes in orthopedic procedures.

Nitinol’s superelasticity provides medical devices with exceptional durability and flexibility. This is especially important in applications where devices are subjected to mechanical stress, such as guidewires, stents, and bone fixation devices. The flexibility ensures that devices can bend, flex, and navigate complex anatomical structures without compromising their integrity.

The shape memory effect in Nitinol enables precise and reliable deployment of medical devices. For instance, Nitinol stents and catheters can be compressed for easy insertion and then expand to their predetermined shape once deployed, ensuring optimal performance in vascular interventions and other medical procedures.

Nitinol’s biocompatibility is one of the key reasons it is widely used in medical devices. When used in implants, Nitinol poses minimal risk of adverse body reactions, ensuring that it can remain inside the body for extended periods without causing harm. Additionally, its corrosion resistance further enhances its longevity in biological environments.

The potential applications of Nitinol in medical technology are continuously expanding. Its superelasticity and shape memory properties make it ideal for a wide range of emerging medical devices. As research progresses, we can expect to see Nitinol used in more personalized implants and minimally invasive surgical tools, providing better solutions for patients.

Ongoing innovations in Nitinol alloys are enhancing the material's properties, enabling it to be used in even more specialized medical applications. For example, researchers are developing modified Nitinol alloys with tailored properties, such as higher strength or specific phase transformation temperatures, to meet the needs of complex medical procedures.

Advancements in manufacturing techniques, such as 3D printing and laser cutting, are improving the production of Nitinol-based medical devices. These innovations allow for the creation of highly precise, customized devices that can meet the specific needs of patients, improving both the effectiveness and efficiency of medical treatments.

Nitinol has had a groundbreaking impact on medical technology. Its unique properties, including superelasticity and shape memory, have revolutionized medical devices like stents and orthopedic implants. As the demand for high-performance, biocompatible materials grows, companies like ZHP Medical continue to lead the way in providing advanced solutions. Their innovative Nitinol-based products enhance patient outcomes and reduce recovery times, making them a key player in the future of healthcare. Explore how ZHP Medical's solutions can offer value in medical technology.

A: Nitinol is a nickel-titanium alloy known for its superelasticity and shape memory. It is used in medical technology for devices like stents and guidewires because of its flexibility, biocompatibility, and ability to revert to its original shape when heated.

A: Nitinol enhances medical devices by providing durability, flexibility, and precision. Its shape memory allows for easy deployment of devices like stents, and its superelasticity makes it suitable for complex procedures such as minimally invasive surgeries.

A: Nitinol's unique properties, like superelasticity and biocompatibility, make it ideal for medical devices. It performs well under stress, resists corrosion, and minimizes adverse reactions in the body, ensuring long-term safety and reliability.

A: Nitinol stents are self-expanding, durable, and biocompatible, offering improved blood flow and long-term patency rates. They reduce restenosis and are preferred for minimally invasive procedures, enhancing patient outcomes.

A: Nitinol archwires apply gentle, consistent pressure for faster and more comfortable teeth alignment. Their superelasticity reduces the need for frequent adjustments, speeding up treatment while improving patient comfort.

A: While Nitinol-based devices can be more costly due to the material’s advanced properties, they offer long-term value by reducing complications, improving patient recovery, and ensuring higher success rates in medical procedures.