English ![]()

Views: 0 Author: Site Editor Publish Time: 2026-01-12 Origin: Site

Have you ever wondered how materials can "remember" their shape? Nitinol, a remarkable Nickel-Titanium alloy, does just that.

In this article, we will explore the unique properties of Nitinol, including its shape memory and superelasticity. We’ll also dive into its key applications, from medical devices to industrial innovations.

Nitinol is a unique nickel-titanium alloy, renowned for its extraordinary properties, including shape memory and superelasticity. Composed of roughly 55% nickel and 45% titanium, this alloy behaves differently from traditional metals. It can return to its original shape after deformation, a process that occurs when it is heated beyond a certain temperature. This makes Nitinol incredibly useful for applications requiring precise control over shape and flexibility.

The key to Nitinol’s functionality lies in its shape memory effect. When Nitinol is deformed at a lower temperature, it "remembers" its original form. Upon heating, it returns to its pre-deformed shape. In addition, superelasticity allows Nitinol to withstand significant stress without permanent deformation, providing remarkable flexibility for various applications.

Nitinol was discovered in 1962 at the Naval Ordnance Laboratory (NOL) in the United States. Its discovery came during experiments on heat-resistant alloys. The name "Nitinol" comes from the combination of Nickel, Titanium, and Naval Ordnance Laboratory. Over the years, the material has evolved to serve a wide range of applications, especially in medical devices and aerospace technologies.

Nitinol’s exceptional properties set it apart from other materials. Its combination of superelasticity, shape memory, and biocompatibility makes it ideal for diverse industries, especially medical technology.

One of the most fascinating properties of Nitinol is its ability to “remember” its original shape. When the material is heated to a specific temperature, it reverts to its pre-deformed form. This property is particularly beneficial in creating self-expanding stents and guidewires used in medical applications.

Nitinol also exhibits superelasticity, which means it can return to its original shape even after significant mechanical stress without permanent damage. This feature allows Nitinol to endure considerable deformation, making it suitable for dynamic and flexible applications, like in robotics and medical devices.

Nitinol’s biocompatibility ensures that it doesn’t cause adverse reactions when in contact with human tissue, making it ideal for implants and other medical devices. This property is essential in minimally invasive surgeries, where materials must interact safely with the body.

Nitinol is highly resistant to fatigue and corrosion, allowing it to perform reliably even after repeated cycles of deformation. These attributes make Nitinol an excellent choice for long-lasting medical implants and other high-performance devices used in harsh environments.

Medical Device | Nitinol Application | Advantage of Nitinol |

Cardiovascular Stents | Self-expanding stents for arterial blockage | Shape memory effect allows stents to expand at body temperature |

Orthodontic Braces | Flexible wires for teeth alignment | High elasticity and constant pressure for better alignment |

Guidewires | Used for minimally invasive surgeries | Flexibility and precision to navigate narrow passages |

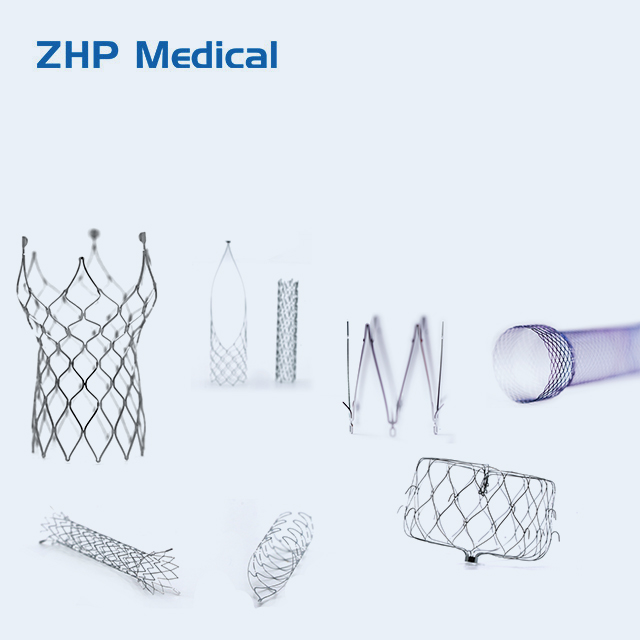

The medical field is where Nitinol’s properties shine the brightest. With its shape memory and superelasticity, it has transformed various aspects of surgical procedures, providing solutions that were previously unattainable.

Nitinol is widely used in cardiovascular stents, devices that help keep blood vessels open in patients with conditions such as arteriosclerosis. The shape memory effect allows these stents to be compressed for delivery via catheter and then expand once deployed inside the body.

In orthodontics, Nitinol wires are commonly used in braces. These wires gradually shift teeth by exerting consistent pressure. Nitinol’s superelasticity makes the wires flexible enough to adapt to the patient’s changing needs while providing optimal results.

Nitinol is also found in guidewires used during minimally invasive procedures. These guidewires are flexible enough to navigate through narrow body passages and then become rigid when needed for precision.

Looking forward, medical Nitinol applications are expected to expand, with potential uses in smart implants and robotic surgeries. Researchers are exploring how Nitinol’s unique properties can help develop devices that react to temperature changes or mechanical stress for improved patient outcomes.

Beyond medicine, Nitinol has found applications in various industrial sectors, thanks to its strength, flexibility, and durability.

In the aerospace industry, Nitinol is used in components that need to withstand extreme temperatures and mechanical stresses. Temperature-sensitive actuators and components that change shape based on environmental conditions benefit from Nitinol’s superelasticity and corrosion resistance.

Nitinol is also crucial for robotics, where it serves as a material for actuators and dynamic motion control systems. Its ability to deform and return to its original shape makes it an ideal choice for robots that require both flexibility and strength.

In consumer products, Nitinol is found in items such as eyewear frames and thermal switches. Its flexibility allows for durable, adjustable components that can adapt to different conditions, providing comfort and longevity.

In the automotive sector, Nitinol is used in self-adjusting systems such as temperature-sensitive valves and actuators. Its ability to react to environmental stimuli makes it ideal for components that require precision and adaptability.

The production of Nitinol involves several critical processes that ensure the material’s unique properties are preserved and optimized.

The heat treatment process is crucial in activating Nitinol’s shape memory effect. During this process, Nitinol is heated to a specific temperature and then cooled rapidly. This controlled process enables the alloy to "remember" its original shape and is essential for ensuring optimal performance in medical and industrial applications.

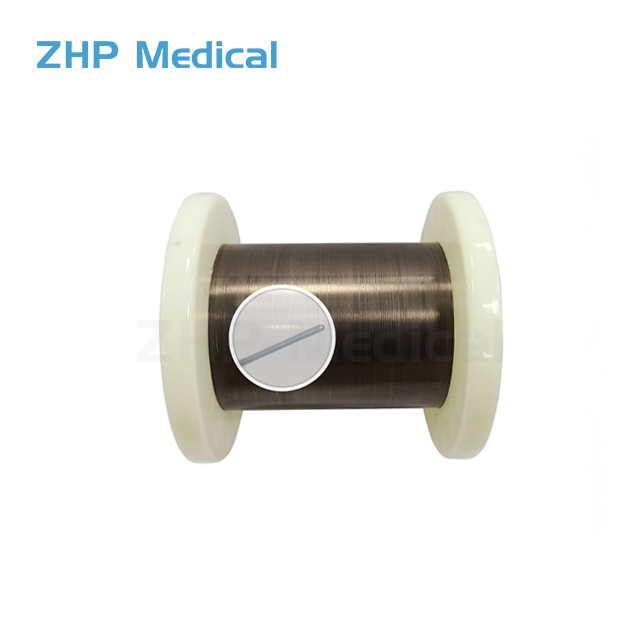

Nitinol wires are produced through a combination of precise alloying and heat treatment. The exact composition of nickel and titanium is carefully controlled to produce wires with different temperature and deformation responses. This allows for customization based on the specific needs of the application.

In many applications, Nitinol is combined with other materials such as stainless steel to create more durable and robust components. This combination enhances Nitinol’s performance, allowing it to withstand more deformation cycles while maintaining its critical properties.

As Nitinol continues to evolve, its future in medical and industrial applications looks promising.

Advances in Nitinol processing techniques are expected to improve the efficiency and cost-effectiveness of Nitinol production. New technologies are emerging that will enable manufacturers to produce Nitinol more efficiently, expanding its potential applications even further.

One exciting area of development is the use of Nitinol in smart materials. Nitinol’s ability to respond to environmental stimuli, such as temperature or pressure, opens up possibilities for applications that go beyond what is currently possible.

The use of Nitinol is expected to grow in fields such as robotics, wearables, and next-gen medical devices. As research and development continue, more industries will benefit from this versatile material, offering innovative solutions for complex challenges.

Nitinol’s unique properties, such as shape memory and superelasticity, make it indispensable in both medical and industrial applications. Its versatility spans across various sectors, from medical devices to robotics and aerospace. Looking ahead, Nitinol will continue to play a pivotal role in technological advancements. At ZHP Medical, we provide high-quality Nitinol solutions, ensuring reliability and performance in every product, helping industries innovate and thrive.

A: Nitinol is a Nickel-Titanium alloy known for its shape memory and superelasticity. It returns to its original shape when heated above a specific temperature and can withstand significant deformation without permanent damage.

A: Nitinol is used in medical devices like stents and guidewires, as well as in aerospace, robotics, and consumer products due to its unique properties such as superelasticity and biocompatibility.

A: Nitinol's biocompatibility, shape memory, and superelasticity make it ideal for medical applications like stents and orthodontic braces, where flexibility and precision are critical.

A: Nitinol is produced by alloying Nickel and Titanium in specific ratios, followed by a heat treatment process that activates its shape memory effect.

A: Due to its complex production process and premium materials, Nitinol can be expensive. However, its durability and performance often justify the cost in high-value applications.

A: Nitinol is highly durable and resistant to fatigue and corrosion, making it an excellent choice for long-lasting medical implants like stents and surgical tools.

A: Yes, Nitinol is widely used in robotics for creating flexible actuators and sensors, thanks to its superelasticity and ability to return to its original shape under mechanical stress.