Comprehensive Fine Processing Capabilities for Medical Device Components

A wide spectrum of fine processing techniques enables the accurate translation of diverse client design specifications.

Other Processing Capabilities

A wide spectrum of fine processing techniques enables the accurate translation of diverse client design specifications.

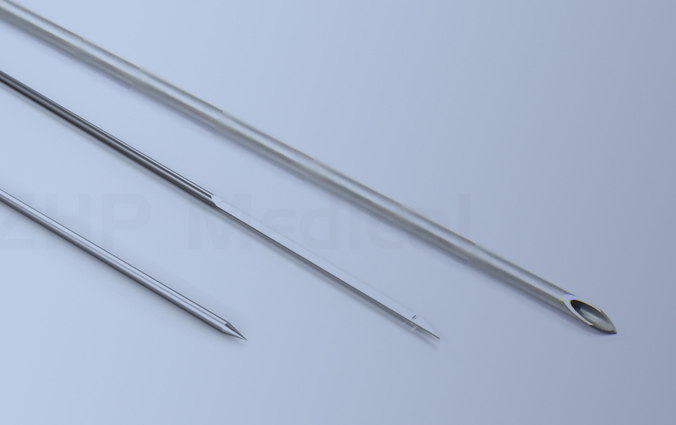

Grinding

Our grinding expertise is routinely applied in the fabrication of various demanding components, including guide wires, mandrels, and specialized needles, demonstrating our commitment to achieving required component geometries through refined machining.

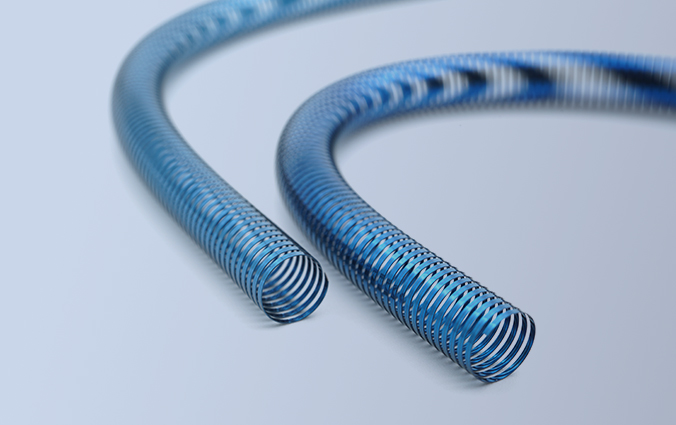

Springs and Microsprings

ZHP Medical manufactures specialized Nitinol (NiTi) and SMA springs for diverse sectors, including medical, aerospace, and industrial applications. We also routinely produce precision coils and microsprings optimized for the medical device industry.

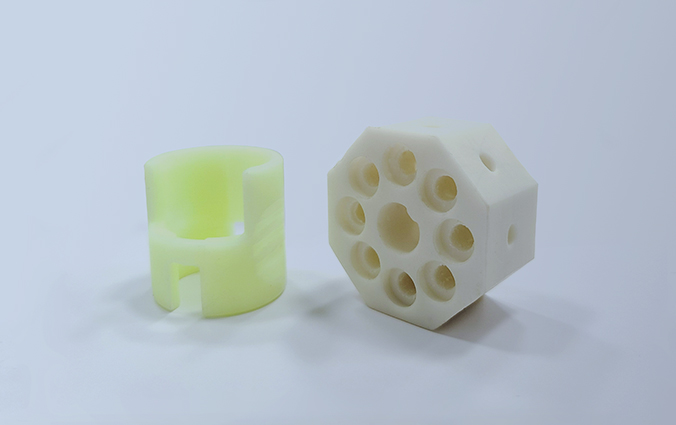

3D printing

ZHP Medical provides advanced additive manufacturing, utilizing 3D printers to process a broad range of materials. Our capabilities cover specialized polymers (PLA, PEEK, etc.) and medical-grade metals (Nitinol, stainless steel, titanium, and cobalt chrome) for diverse component realization.

Wire and Sinker EDM

ZHP Medical utilizes efficient Wire EDM technology to process intricate Nitinol components, achieving tight-tolerance features under minimal stress. Our Sinker EDM machinery further supports micro-applications with exceptionally refined feature production.

Precision Machining

We process materials including NiTi, Stainless Steel, and Titanium. Fabrication utilizes advanced techniques: EDM, CNC turning, and grinding. Components serve critical medical, automotive, and industrial applications.

Needle Processing

Specialized in micro-machining biocompatible alloys (SS, NiTi, CoCr) into extremely fine medical needles. Services include precision grinding, laser cutting, and forming for biopsy, cosmetic, and anesthesia applications.