English ![]()

Views: 0 Author: Site Editor Publish Time: 2026-01-12 Origin: Site

Did you know that the key to some of the most innovative medical devices lies in a unique alloy? Nitinol, a nickel-titanium alloy, is celebrated for its shape memory and superelasticity. This remarkable material is transforming the way medical devices, such as stents and guidewires, are designed.

In this article, we’ll explore how Nitinol is melted and manufactured, and why the melting process is crucial for its role in life-saving medical applications. You’ll gain a deeper understanding of how its properties make it ideal for medical technology.

Nitinol, a remarkable alloy composed of nickel and titanium, is best known for its unique superelastic and shape memory properties. These properties allow it to return to its original shape after deformation and provide flexibility under stress, making it ideal for use in medical devices like stents, guidewires, and implants.

The melting process of Nitinol is crucial in achieving these extraordinary properties. The ability of Nitinol to "remember" its original shape and undergo superelastic deformation depends on the precise temperature control and processing during its production. If the melting process isn't carefully controlled, it could lead to the loss of these beneficial properties, making the alloy unsuitable for medical use.

In the context of medical devices, Nitinol's properties must meet rigorous standards for strength, flexibility, and durability, all of which are influenced by the melting process. The process needs to ensure that these critical characteristics are retained, as they directly affect the performance of medical devices that save lives.

The melting points of the constituent metals in Nitinol, nickel (1453°C) and titanium (1670°C), are high compared to many other metals. This means the melting process for Nitinol requires specialized equipment and techniques to maintain control over the temperature and prevent contamination. The precise melting of Nitinol is crucial because even slight variations in temperature can significantly affect the alloy's properties.

Common techniques used in the melting of Nitinol include:

Technique | Description | Advantages |

Vacuum Induction Melting (VIM) | Nitinol is melted in a vacuum induction furnace to avoid contamination. The vacuum prevents oxidation and other impurities. | Ensures a pure alloy, free from oxidation and contamination. |

Vacuum Arc Remelting (VAR) | This method involves melting the alloy in a vacuum arc furnace. It provides high-quality material by removing impurities. | Improves the uniformity and consistency of the material. |

These techniques ensure that the final Nitinol alloy has consistent properties, crucial for its use in medical devices. VIM and VAR are used in combination to refine the material, ensuring that it meets the high-quality standards required for medical applications.

The melting process directly influences the alloy’s crystal structure, which in turn affects the shape memory and superelasticity of Nitinol. The shape memory effect occurs when the material "remembers" its pre-deformed shape and returns to that shape once heated above a certain temperature. Similarly, superelasticity allows the material to undergo large strains without permanent deformation and return to its original shape when the stress is removed.

The melting temperature and the subsequent cooling process are key factors in determining these properties. If the material is heated too rapidly or too slowly, the phase transition that is required for these properties may not occur correctly, leading to a reduction in performance.

The process of manufacturing Nitinol begins with pure titanium and nickel. These metals are combined in an exact atomic ratio of 1:1, which is crucial for achieving the desired shape memory and superelastic properties.

● Nickel: Provides the shape memory properties when the alloy is heated.

● Titanium: Gives the alloy its high strength and biocompatibility.

Once the materials are mixed, they are heated and melted under controlled conditions. The composition of the alloy must be precisely maintained to ensure that the material's physical properties are consistent and suitable for medical use.

Once the raw materials are prepared, they undergo a vacuum melting process to avoid contamination from atmospheric gases. This ensures that the material remains pure, which is essential for the functionality and safety of medical devices.

The vacuum furnace used in the melting process provides an oxygen-free environment that prevents oxidation of the materials. After the melting, the Nitinol alloy is cast into ingots, which are later used to create specific device components such as wires, stents, and guidewires.

The next phase involves heat treatments like annealing or aging, which further refine the mechanical properties of the alloy. These treatments ensure that the alloy achieves the correct balance of strength and flexibility.

Tip: Using vacuum melting prevents impurities and ensures a consistent alloy, which is critical for the performance of Medical Nitinol in medical devices.

After the alloy is produced, Nitinol is formed into various shapes suitable for medical devices. Common forms include:

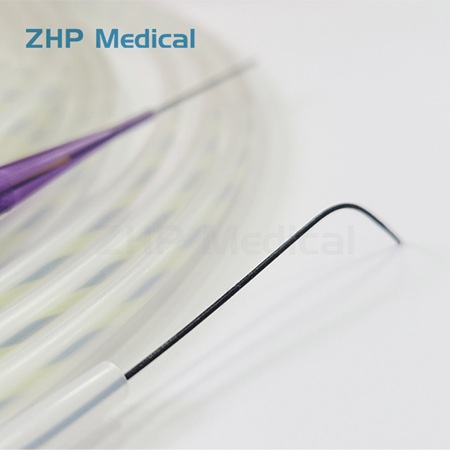

● Wires: Used for guidewires, stents, and surgical tools.

● Sheets: Used to manufacture laser-cut stents and other implantable components.

● Bars: Used in structural components like orthopedic implants.

The forming process involves shaping the alloy into the required form, often using techniques like laser cutting, electroforming, and die stamping. Each technique ensures that the final product meets the rigorous specifications for medical use, providing both strength and flexibility.

The melting process of Nitinol plays a key role in determining its mechanical properties, such as strength, flexibility, and durability. By carefully controlling the temperature during melting, manufacturers can influence the material's crystal structure, grain size, and phase transitions, all of which affect its overall performance in medical devices.

These properties are critical for medical devices like stents, which need to expand within blood vessels without breaking, and guidewires, which need to be flexible enough to navigate complex pathways in the human body.

The precise control over the melting process ensures that Nitinol maintains its mechanical strength and flexibility. For medical devices, safety is a top priority. If Nitinol is improperly processed, it may fail to perform as expected, leading to device malfunction.

By maintaining strict control over the melting and cooling processes, manufacturers can minimize defects like cracks or irregularities that could lead to device failures during use. This is especially important for implantable devices, which must maintain their performance over extended periods.

In practical applications, such as stents, the melting process determines how well the material can perform its task. Stents need to expand and maintain their shape after being inserted into a blood vessel. If the Nitinol alloy is not properly melted and processed, the stent may not perform correctly, potentially leading to patient complications.

Similarly, guidewires must be flexible and strong enough to navigate complex vascular structures. The melting process influences how these devices perform under real-world conditions.

Quality control during the melting process is critical to ensuring that Nitinol meets the necessary standards for medical use. During the melting, manufacturers closely monitor the temperature and purity of the alloy to ensure that it remains free from impurities like oxides or foreign particles.

By using advanced techniques like optical microscopy and scanning electron microscopy, manufacturers can inspect the Nitinol for defects and inconsistencies. These methods allow for the detection of any issues that could compromise the integrity of the final medical device.

After Nitinol is produced, it undergoes rigorous testing to ensure its suitability for medical applications. Key tests include:

● Optical Microscopy: Used to examine the grain size and structure of the Nitinol alloy.

● Scanning Electron Microscopy (SEM): Used to detect surface defects or inclusions that could impact the material's performance.

These tests help ensure that the Nitinol meets the high standards required for medical devices like stents, guidewires, and implants.

A well-controlled melting process ensures that Nitinol retains its strength and flexibility over time. For implantable devices, such as stents, it is crucial that the material maintains its properties throughout the device’s lifespan, ensuring long-term safety and functionality.

By adhering to strict quality control measures during the melting process, manufacturers can ensure that Nitinol-based devices will continue to perform reliably throughout their intended use.

In this article, we explored the critical role of precise melting techniques in manufacturing Nitinol. These methods significantly impact its superelasticity and shape memory, ensuring that Nitinol-based medical devices perform safely and effectively.

Nitinol continues to revolutionize medical technology, improving patient outcomes and enabling innovative treatments across various medical fields.

Looking ahead, advancements in melting techniques will further enhance Nitinol’s use in medical devices, paving the way for even more effective and reliable solutions in the healthcare industry. ZHP Medical offers high-quality Nitinol components, ensuring top-tier performance in medical applications.

A: Nitinol is a nickel-titanium alloy known for its unique shape memory and superelasticity. These properties make it ideal for medical devices like stents and guidewires, allowing them to perform reliably inside the human body.

A: Nitinol is made by melting nickel and titanium in a controlled environment, often using techniques like vacuum induction melting (VIM) and vacuum arc remelting (VAR). These methods ensure the alloy has the desired properties for medical use.

A: The melting process of Nitinol influences its shape memory and superelasticity. Precise control of temperature during melting ensures that these properties are preserved, which is crucial for the safe and effective performance of medical devices.

A: The melting point of Nitinol is crucial to its mechanical properties. If the melting temperature is not controlled, it can negatively impact the material’s strength, flexibility, and biocompatibility, which are essential for medical applications.

A: Nitinol offers superelasticity and shape memory, allowing medical devices to perform complex tasks like expanding in blood vessels or navigating the body’s vascular system with ease. These benefits make it ideal for stents and guidewires.