English ![]()

Views: 0 Author: Site Editor Publish Time: 2026-01-12 Origin: Site

Nitinol, a nickel-titanium alloy, is transforming the medical device industry. Its unique shape memory and superelastic properties make it essential for implants.

In this article, we will explore how Nitinol's characteristics drive innovation in medical implants. You'll discover the challenges and advantages of designing and manufacturing with Nitinol for critical applications.

Nitinol's shape memory effect and superelasticity are the two primary properties that make it ideal for medical implants.

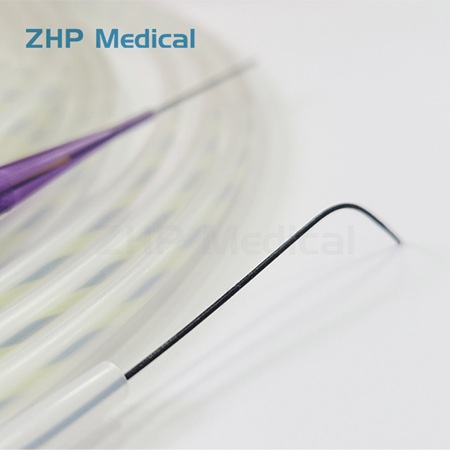

● Shape Memory: Nitinol can "remember" its original shape after being deformed. When heated above a certain temperature, it returns to its predefined shape. This makes it especially useful for implants that need to expand or contract once inside the body, such as stents and guidewires.

● Superelasticity: Nitinol is also superelastic, meaning it can undergo large deformations and return to its original shape without permanent damage. This property is essential for medical implants that need to withstand repeated movements and stress within the body.

These unique characteristics of Nitinol allow it to perform in challenging conditions where other materials like stainless steel would fail, making it highly suitable for life-saving medical devices.

Nitinol’s role in medical implants extends beyond its flexibility and strength. It offers several key benefits, making it a preferred material in the medical device industry:

● Biocompatibility: Nitinol is highly biocompatible, meaning it can be safely used in the human body without causing adverse reactions. Its ability to integrate with biological systems makes it ideal for long-term implantation.

● Corrosion Resistance: The alloy forms a protective oxide layer, which makes it resistant to corrosion in the body, ensuring the longevity of implants like vascular stents and orthopedic devices.

● Flexibility and Durability: Nitinol’s superelasticity ensures that it remains flexible under pressure but doesn't lose its structural integrity. This feature is especially critical in devices that need to bend and return to their original form, such as guidewires.

Nitinol outperforms other materials like stainless steel in applications requiring high precision, durability, and performance under mechanical stress. Its ability to withstand large amounts of stress without permanent deformation or failure makes it invaluable for life-saving medical devices.

Despite its many advantages, there are some challenges associated with designing and manufacturing Nitinol implants:

● Low Machinability: Nitinol is a difficult material to machine due to its hardness and low machinability. Special manufacturing techniques, such as laser cutting, micro-machining, and electroforming, are required to shape the material precisely.

● Fatigue Resistance and Precision: Ensuring that Nitinol implants can withstand repeated stress cycles without failure is a major design challenge. This requires careful consideration of material properties, geometry, and the environment in which the implant will function.

Working with Nitinol requires specialized knowledge and advanced technology to produce reliable and precise medical implants. Manufacturers must focus on overcoming these challenges to create devices that meet stringent medical standards.

The process of manufacturing Nitinol implants begins with sourcing high-quality raw materials. The quality and composition of the Nitinol used are crucial for the performance of the final implant.

● Quality Control: Manufacturers must source Nitinol from reputable suppliers who meet strict quality standards. This ensures that the alloy has the right mix of nickel and titanium to achieve the desired mechanical properties.

● Material Composition: The precise ratio of nickel to titanium affects the transformation temperatures and mechanical behavior of Nitinol. Manufacturers must ensure the raw material meets the exact specifications required for the intended medical application.

To maintain consistency and reliability, suppliers must validate multiple sources of Nitinol to mitigate the risk of supply disruptions. This ensures the uninterrupted production of high-quality medical implants.

One of the most critical aspects of Nitinol implant manufacturing is heat treatment. This process ensures that the Nitinol exhibits the desired properties of shape memory and superelasticity.

● Solution Annealing: The Nitinol alloy is heated to a high temperature to promote a homogenous microstructure. This step helps define the transformation temperatures of the alloy, which is critical for the implant's function.

● Quenching and Aging: After solution annealing, the alloy is rapidly cooled (quenched) to lock in the desired microstructure. Aging is then performed at a lower temperature to enhance the alloy's mechanical properties and shape memory effect.

By controlling the heat treatment process, manufacturers can fine-tune the properties of Nitinol to ensure it meets the specific requirements of each medical application.

The manufacturing of Medical Nitinol implants requires specialized techniques to shape and refine the material to meet the necessary specifications:

● Laser Cutting: Laser cutting is commonly used to produce precise shapes in Nitinol implants, such as stents. The high precision of laser cutting ensures that the dimensions of the implant are accurate and meet medical standards.

● Micro-machining and Electroforming: These techniques are used to create highly detailed, small-scale components with fine tolerances. Micro-machining allows for intricate cuts and designs, while electroforming can deposit thin layers of Nitinol onto a mold or template.

These advanced manufacturing techniques are essential for producing high-quality Nitinol-based implants that meet the rigorous demands of the medical industry.

Finite Element Analysis (FEA) plays a crucial role in the design of Nitinol implants. This computer simulation technique allows engineers to model the mechanical behavior of implants under various conditions.

● Simulating Mechanical Behavior: FEA helps predict how the implant will perform under stress, strain, and deformation, ensuring it will function as intended within the human body.

● Reducing Prototyping Time: FEA allows for rapid iterations of design testing without the need for physical prototypes. This reduces time to market and helps identify potential issues early in the design phase.

FEA is particularly valuable when designing complex Nitinol implants like stents, where precise control over mechanical properties is essential for successful performance.

Design for Manufacturability (DFM) ensures that the Nitinol implant can be efficiently and cost-effectively produced without compromising quality.

● Cost-Reducing Design Changes: Early-stage design evaluation helps identify areas where the design can be optimized for manufacturing, reducing material waste and production time.

● Maintaining Implant Functionality: While cost reductions are important, they should never come at the expense of the implant’s functionality. DFM ensures that the final product meets all medical and regulatory standards.

Designing Nitinol implants with manufacturability in mind helps streamline production and improves the overall cost-effectiveness of medical device manufacturing.

The electropolishing and passivation processes are essential for enhancing Nitinol’s corrosion resistance and ensuring its biocompatibility.

Surface Treatment | Benefit | Key Process |

Electropolishing | Removes micro-cracks, smoothens surface | Uses electrical currents to polish the implant surface |

Passivation | Forms a protective oxide layer for corrosion | Creates a titanium oxide layer to improve biocompatibility |

Corrosion Resistance | Enhances implant longevity | Critical for implants in environments like blood vessels |

These surface treatments significantly improve the longevity of Nitinol implants, particularly in high-stress environments like blood vessels or joints.

Before Nitinol implants can be used in patients, they must undergo biocompatibility testing to ensure they do not cause adverse reactions in the body.

● Biocompatibility Tests: Tests such as cytotoxicity, irritation, and sensitization are performed to assess the safety of Nitinol implants. These tests ensure that the material does not provoke an immune response or cause toxicity when implanted.

● Regulatory Compliance: Nitinol implants must meet strict regulatory standards, including those set by ISO 10993 and the FDA, to ensure their safety and effectiveness in medical applications.

Biocompatibility testing is a critical step in the development of Nitinol-based implants, ensuring they are safe for long-term use in the human body.

Nitinol’s unique properties, such as shape memory and superelasticity, make it ideal for medical implants. Its ability to withstand mechanical stress and return to shape is crucial for devices like stents and heart valves.

The future of Nitinol in medical implants looks promising, with advancements in manufacturing techniques driving innovations. ZHP Medical continues to lead in this field, offering high-quality Nitinol-based products that provide unmatched performance and reliability in critical medical applications.

A: Nitinol is a nickel-titanium alloy known for its shape memory and superelasticity. These unique properties allow it to return to its original shape after deformation, making it ideal for medical implants like stents and guidewires.

A: Nitinol’s shape memory allows implants to expand or return to a predetermined shape inside the body, ensuring proper functionality in vascular devices and orthopedic implants, improving patient outcomes.

A: Nitinol offers excellent biocompatibility, corrosion resistance, and durability. These properties make it a top choice for life-saving implants like heart valves and stents, especially for minimally invasive procedures.

A: Nitinol’s hardness and low machinability make it challenging to work with conventional techniques. Specialized methods like laser cutting and micro-machining are required for precise manufacturing of Nitinol implants.

A: The cost of manufacturing Nitinol implants can be higher due to the specialized raw materials and advanced manufacturing techniques required. However, the long-term benefits in terms of patient safety and device durability justify the investment.